The founder began with a modest electric shop and then added assembly, testing and basic warranty service to offer budget lighting to neighbourhood customers who found branded bulbs too costly.

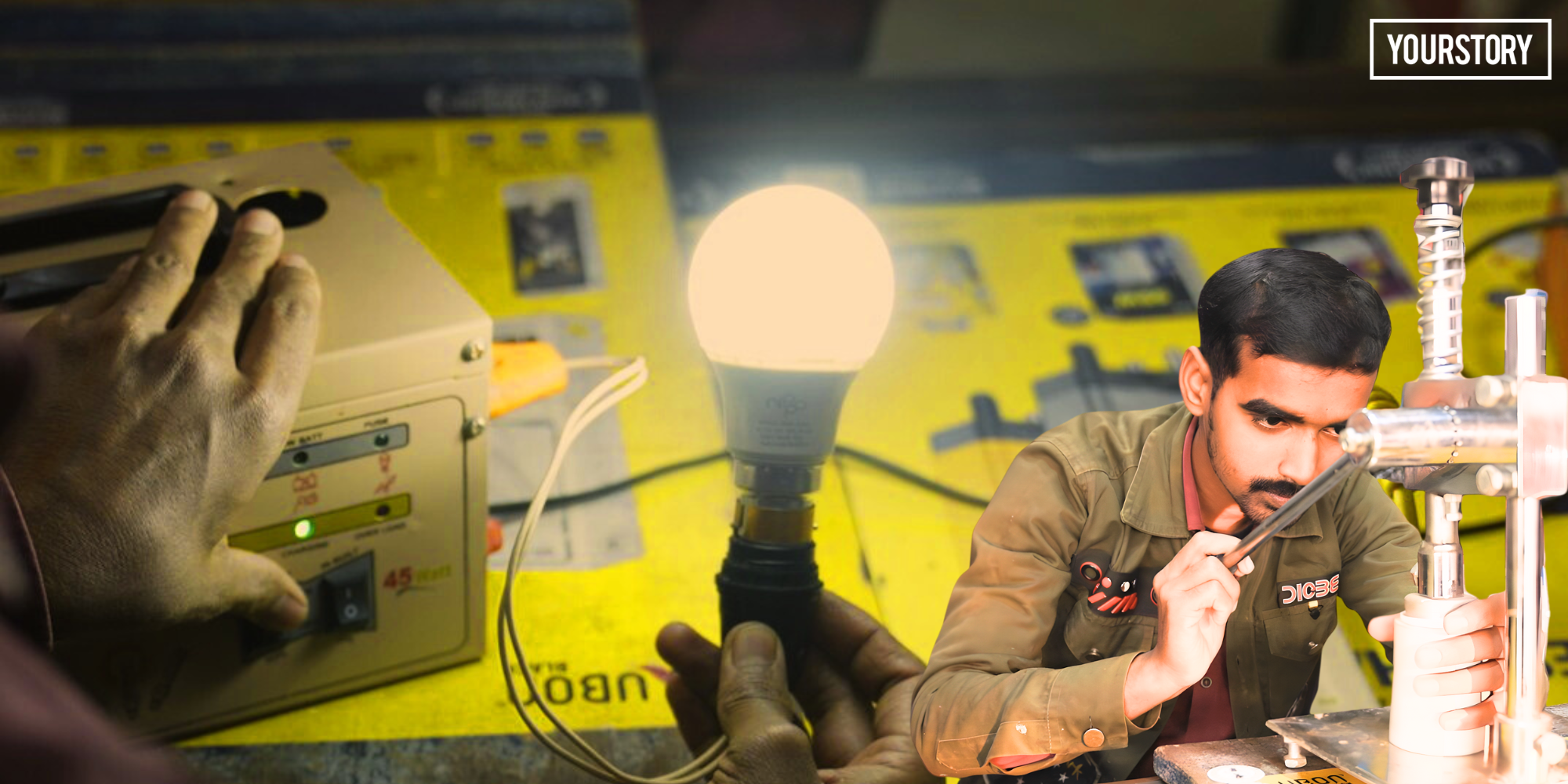

Inside the workshop

Kumar says he installed a compact LED bulb assembly setup, sources raw materials from multiple suppliers, and keeps margins lean so that prices remain accessible.

Each batch is assembled, checked for brightness and faults, and released to the local market with a basic guarantee. If a unit fails, he repairs or replaces it on the spot, a practice that has helped him earn repeat customers.

The production workflow is straightforward. He acquires driver boards, housings, LEDs and caps from suppliers, assembles them in sequence, solders the joints, tests the output, and then packs the units for sale.

Most of the learning came through mobile internet use, especially YouTube tutorials, and from visits to local employment fairs where machinery suppliers and trainers demonstrate equipment and share contacts.

Why LEDs and how he found suppliers

Kumar observed that branded bulbs were priced out of reach for many buyers in his town. He began searching online for machinery options and raw material sources, contacted vendors by phone, and compared costs.

He says discovery was not difficult. Supplier videos and contact details available on YouTube helped him shortlist machines and negotiate purchases. Once the tools arrived, he practised soldering and basic diagnostics, then started small-scale sales from his existing shop counter.

Financing and training

The business received a push when he applied under the Mukhyamantri Yuva Udyami Vikas Abhiyan (CM YUVA) Yojana. As part of the process, he attended short training sessions that covered basic machine operation, sourcing and record-keeping.

The working capital helped him buy a machine, stock raw material and expand output.

Kumar began experimenting during the lockdown period, when repair jobs such as wiring, small appliance fixes, and lighting maintenance sustained the shop. Over time, the trials matured into a product line of LED bulbs backed by a local warranty.

He credits district and Nagar Panchayat outreach for nudging youth towards self-employment, and says online videos filled the skills gap.

Founder’s journey and impact

The founder notes that while his arts graduation provided him with an academic base, most manufacturing know-how came from hands-on iteration.

By reinvesting earnings and servicing the loan on time, he reports steadier cash flows. Day-to-day life has improved, with fewer money worries and a clearer growth path, he says.

While the unit is small, the focus on after-sales support and fair pricing has helped it stand out in nearby markets. Kumar plans to keep prices low, maintain quality checks, and rely on word of mouth.

For buyers, the proposition is simple a bright bulb at a modest price, with a local face accountable for warranty.

For many first-time entrepreneurs in Tier III markets, Kumar’s experience offers a practical playbook — learn from openly available content, start with a service adjacency, formalise with a small loan, keep margins reasonable, and build trust through quick fixes rather than lengthy claims.

Discover more from News Link360

Subscribe to get the latest posts sent to your email.